Who Invented the Metal Roof?

Today, we’re nerding out on the fascinating world of metal roofing. And let me tell you, it’s not just some fancy new trend; metal roofs have a surprisingly long and awesome history. So, buckle up, because we’re about to get our hands (metaphorically) dirty with how these incredible roofs are made!

The Official Metal Roofs Origin: A Blast from the Past!

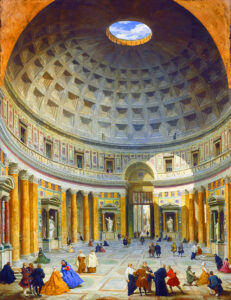

You might think metal roofs are a modern marvel, but prepare to have your mind blown! Believe it or not, the first recorded use of metal for roofing goes way, way back to ancient times. The Pantheon in Rome, built around 126 AD, famously used bronze tiles for its dome. That’s right, bronze! Talk about durability!

But who was the true pioneer of metal roofing as we know it today? While various cultures dabbled in metal for centuries, the real game-changer was standing seam metal roofing, which we largely owe to the French in the 18th century. They developed techniques to create long, continuous panels with raised seams, which drastically improved weather resistance. Think of it: no more leaky overlaps! It was a brilliant, elegant solution that really set the stage for modern metal roofing.

For more historical tidbits, you can check out this neat article from Classic Metal Roofs on the history of metal roofing.

From Raw Material to Perfect Roof: How It’s Made!

Okay, so we know metal roofs have ancient roots, but how exactly do they go from a big roll of metal to that sleek, protective shield over your head? This is where the magic happens, and it’s seriously cool.

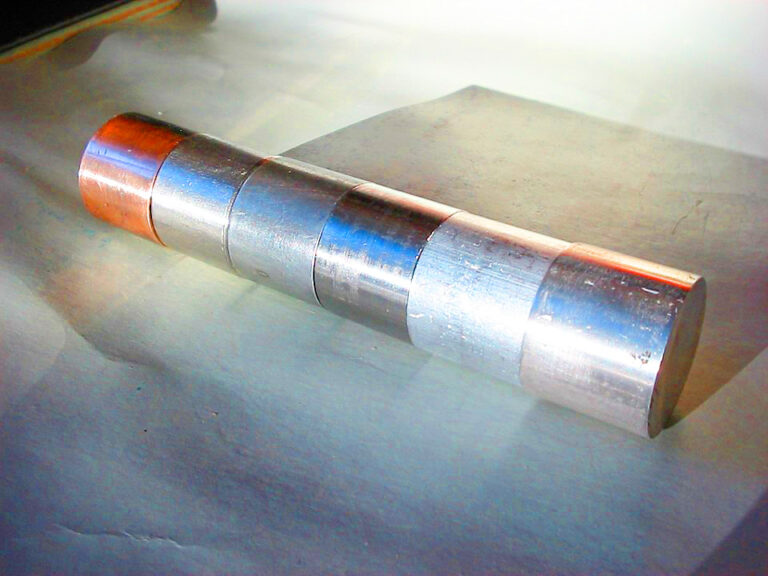

The journey usually starts with a massive coil of metal. We’re talking steel, aluminum, copper, or zinc – each with its own superpowers! Steel is probably the most common, often galvanized (coated with zinc) for extra corrosion resistance. Aluminum is super lightweight and resists rust like a champ, making it perfect for coastal areas. Copper? Oh, copper! It develops that gorgeous, unique patina over time. And zinc? It’s incredibly durable and self-healing!

Once they have their chosen metal, it’s time for the manufacturing process.

1. The Uncoiling and Leveling:

Imagine a giant paper towel roll, but instead of paper, it’s a thousand-pound coil of metal. This coil gets unspooled and sent through a leveling machine to flatten out any kinks or bends. You want that metal perfectly flat before you start shaping it!

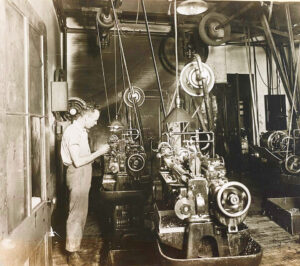

2. Roll Forming:

The Transformation! This is where the real fun begins! The flattened metal then enters a roll forming machine. This isn’t just one big press; it’s a series of rollers, each one progressively bending and shaping the metal into the desired profile. Think of it like a highly choreographed dance, with each roller adding a subtle curve or angle until, voila!, you have a perfectly formed roofing panel. Whether it’s a standing seam panel, a corrugated panel, or a metal shingle, these rollers are the unsung heroes.

3. Coating and Finishing:

The Super-Suit! Once the panels are shaped, they often get a protective coating. This is where the color comes in, and it’s not just for looks! These coatings, often made of Kynar 500® or similar fluoropolymer resins, are incredibly durable. They resist fading, chipping, and chalking, even under the harshest sunlight. This is what gives your metal roof its long-lasting beauty and protection. Some panels might also get an additional clear coat for extra shine and UV protection.

4. Cutting and Packaging:

Ready for Action! Finally, the continuous panels are cut to the specified lengths. Then, they’re carefully stacked, bundled, and prepared for shipping. Each bundle is like a superpower package, ready to be transformed into a tough, beautiful roof.

It’s truly a marvel of engineering, from the raw material to the finished product. The precision involved in roll forming, the advanced coatings, and the sheer strength of the metal itself – it all adds up to a roofing material that’s built to last for decades, often even longer than a traditional asphalt shingle roof. And this is why metal roofing is such a fantastic choice for your home, whether you’re looking for a new metal roof installation or considering a full roof replacement.

Why Metal Roofing is the Smart Investment!

So, now you know how these bad boys are made, but why should you care? Because knowing the craftsmanship that goes into them helps you appreciate their incredible benefits! Metal roofs are:

Durable as a shield:

They can withstand extreme weather, from hail to high winds, much better than traditional materials. This translates to less worry about roof repair down the line.

Energy efficient:

They reflect solar radiant heat, which can significantly reduce your cooling costs. Who doesn’t love saving money on their energy bill?

Long-lasting:

We’re talking 50 years or more, easily! That’s a serious return on your investment.

Environmentally friendly:

Many metal roofs are made from recycled content and are 100% recyclable at the end of their incredibly long life.

Aesthetically versatile:

From classic standing seam to metal shingles that mimic wood or slate, there’s a style and color to match any home’s architecture.

If you’re thinking about a new roof, especially a roof installation, you should definitely be looking into metal roofing near you. It’s an investment that pays dividends in protection, longevity, and even curb appeal.

Looking for Metal Roofing Excellence in Northeast Ohio?

When it comes to getting a top-notch metal roof for your home, you want a company that knows their stuff. That’s where Eagle Eye Roofing, LLC, swoops in! Servicing the Akron, Canton, and Uniontown, Ohio areas, Eagle Eye Roofing, LLC, is a trusted Google 5-Star rated Metal Installation roofing company. They’re all about quality craftsmanship and making sure you get the best metal roof for your home, expertly installed with care and precision.